Thrive Agritech is changing the way the world cultivates by advancing the science of LED grow lighting

Thrive Agritech is enabling indoor farmers to do more with less by pushing the technological boundaries of commercial LED grow lights. We have been at the forefront of LED technology and horticultural lighting for several years, helping our customers with a unique blend of scientific know-how and cultivation experience. Lighting is often the most critical component of a successful indoor farm and it is our mission to ensure that it is also the highest performance.

Customer Spotlights

Indoor Single Tier

Greenhouse Cannabis

Greenhouse Horticulture

Greenhouse Efficiency Rebate

Applications

Whether you are growing kale in a greenhouse or cannabis in a warehouse, Thrive Agritech’s LED lighting products are designed to uniformly and efficiently provide Photosynthetically Active Radiation (PAR) that grows great plants.

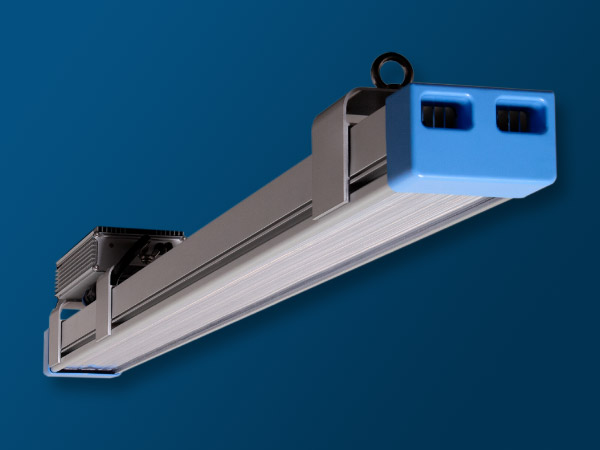

Introducting OptiDrive!

Remote power systems for new construction and retrofits that lower costs of your lighting system while improving reliability.

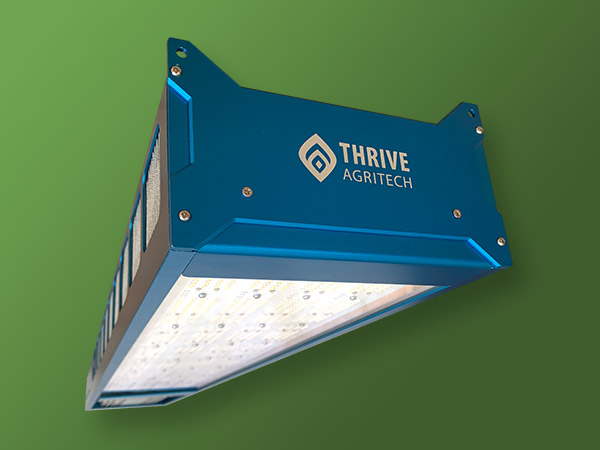

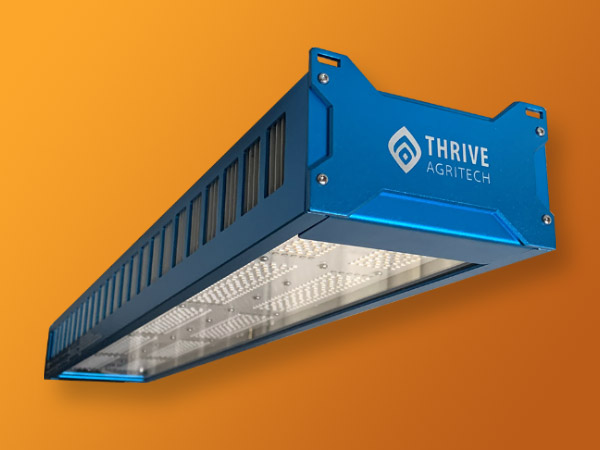

Products

High performance grow lights with patent-pending LED technology that grow the best plants possible. Lights that are easy to install and maintain, UL listed and backed with a 5-year warranty to ensure peace of mind.

Customers Include: